The Definitive Guide to Returns Management for D2C Brands

Simplifying Returns Management for Shopify Brands

Product returns are one of the most pervasive, complex problems in e-commerce. As much as 30% of sales come back as returns. As you scale your D2C business, returns will increasingly become an issue.

That leaves the question: What do we do with all of these returns?

To that, we ask: Do you want to optimize for fewer returns or more profit?

Any seasoned business owner, e-commerce manager, or operations lead will choose more profit.

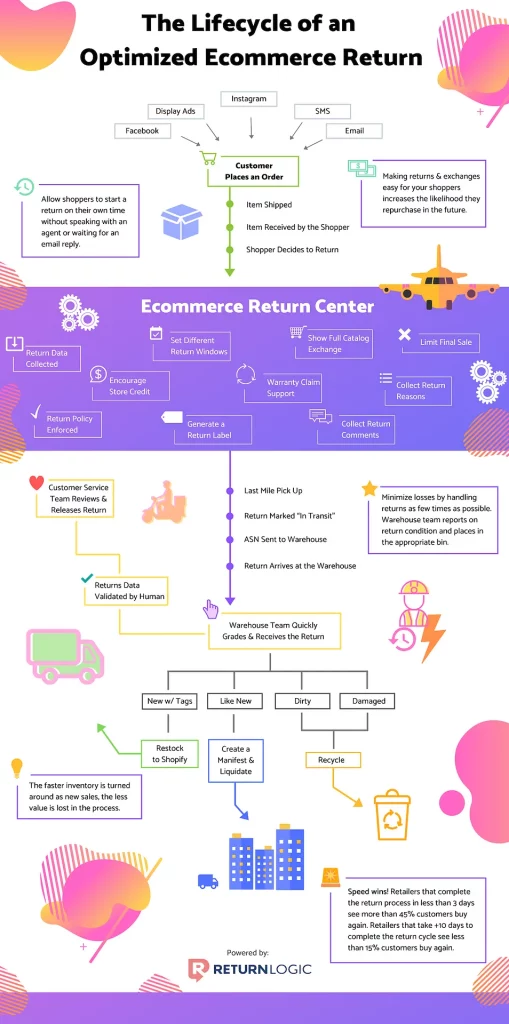

The answer begins and ends with creating an amazing experience for your shoppers. Three pillars deliver this experience:

- A Shopper-Friendly Return Policy

- An easy Process for Creating a Return

- Efficient Operations that Resolve Returns FAST

As we’ve learned, you can’t capture an effective return management process in one initiative. It’s a holistic approach that culminates in a single methodology.

We call this methodology Returns Optimization.

Returns Optimization asserts that returns are not a problem, but rather an opportunity to learn about areas of friction in your shopper’s journey. The fruit of these lessons is greater customer lifetime value, a more efficient e-commerce operation, and increased profits.

Because returns are complicated, return management software solutions like ReturnLogic have emerged to systemize the process, enforce policy rules, and clarify how returns impact the business.

Before we explain how to implement a streamlined return management process, it helps to define a few key terms.

Return Management Terms Defined:

Return Policy – The rules for what can be returned & exchanged that treat all customers fairly. It contains several different components: Return types indicate if the customer requests a refund, exchange, store credit, or warranty. Return windows cover when you can return those products, return rules govern what you can and can’t return, and return reasons address the cause for the return.

Return Center – A simple customer-facing portal where shoppers create a return and shop for an exchange following the rules and policies set by the retailer.

Return Management – All the policies, rules, workflows, and processes that build a return for a shopper, and the systems used by the retailer to receive, grade, and complete the return.

Reverse Logistics – The processes of handling a return from the shopper to the retailers and through to the final destination to maximize the product’s recovery value.

Product Dispositions – A set of conditions that classify a returned product’s grade. For example, “New w/ Tags,” “Dirty,” or “Damaged,” etc.

Returns Data – The data generated by customers, products, orders, and resulting returns, and the connections between each.

Return Optimization – Continuous improvement strategies that use Return data to enhance the experience for the shopper, improve operational efficiency, and grow profits.

Return Management: The Confluence of Two Complex Worlds

ReturnLogic Founder and CEO Peter Sobotta makes it clear that returns can be further segmented into the front-end side – return management – and the back-end side – reverse logistics.

Return management creates a frictionless experience for shoppers while enforcing return policies.

On the other side, reverse logistics is all about efficiently handling returned products and recovering their maximum value. This process includes restocking products back into inventory, selling them through an off-price channel, liquidating, or recycling them.

Return management feeds reverse logistics.

The two pieces relay information back and forth, and both depend on the operational processes that a retailer has in place.

You can see that the return center is the gateway between return management and reverse logistics. It’s where the customer experience transitions into the workflows of a return management solution.

Customers Expect FAST Returns – and That’s Hard to Deliver

At this stage in e-commerce, a combination of shopper’s expectations and competition results in pressure for retailers to provide a blindingly fast forward supply chain.

Just look at Amazon unleashing same-day delivery on over 1 million items in 14 metropolitan hubs – and in some cases, it’s free. A similar demand for impression is building in the reverse supply chain, as well. The problem is, much of e-commerce has not kept up.

As stated on Commerce Clarified:

“Reverse logistics is one of the few remaining areas of the e-commerce supply chain to be efficiently optimized. While many companies have begun making investments to improve warehouse efficiencies and/or post-purchase customer experiences, many still leverage an inefficient combination of spreadsheets, images, improperly managed areas within distribution centers, and unconnected systems of local resellers/liquidators.”

The Life of a Returned Product

Once the returned product arrives back at the retailer’s warehouse or 3PL, the journey has just begun. At this point, the warehouse team must process the return as fast as possible.

Intelligently crafted automation enables merchants to streamline the most repetitive, labor-intensive tasks while allowing them to maintain visibility and control over their return process.

Returns cost retailers money for each touchpoint from an employee and every minute they sit in the warehouse. On top of that, shoppers want returns dealt with fast.

Keep in mind that product returns are an opportunity for customer satisfaction. As Sobotta emphasizes, “You can maximize the recovery value [of returned goods] only after you’ve solved the customer experience problem.”

Return processing speed is a key back-end component of a positive customer experience. Monitoring the RMA Status Report will help operations teams understand where returns are getting stuck in the process.

As soon as the returned merchandise is processed, the next priority is directing it to its new path, whether it’s immediately restocking the product into inventory, cleaning or repairing it for restock, or an aftermarket option like wholesaling or liquidation. Here’s where product dispositions come into play.

How Product Dispositions Maximize Product Recovery Value

The disposition is assigned to a product by the team that receives returns in the warehouse. They dictate what happens with the product.

While it seems appealing to try to refurbish as many products as possible to be in perfect restock condition, it simply isn’t scalable when a retailer’s volume grows.

You need to consider what you think the product could be worth versus what it’s worth right now.

As one of our retailers stated about his category, “Fashion is aging – you don’t want to sit on it too long. You want to turn it to cash fast.”

With apparel in particular, by the time a product is returned and processed by the retailer, it may be outdated.

Sobotta cites the subjectivity of dispositions as a scourge of recovery value. “If it’s not new with tags, what is it?”

This uncertainty not only adds complexity slowing down the process. It also creates risk for the aftermarket buyer, which limits the product’s value.

Within apparel, where the asset value is relatively low, for example, Sobotta recommends that retailers keep their dispositional flows simple, potentially just differentiating returned products as either “New with Tags” or “Liquidation.”

Preventing ambiguity and errors in this process is crucial to reduce the headaches and financial burden of product returns.

Quickly Restocking “New with Tags” Inventory to Shopify

D2C brands live and die by inventory. For this reason, smart Shopify inventory management is necessary. With every minute a product spends in transit, on the warehouse dock, or in a pile, you’re losing money.

When a return arrives at the warehouse, a team member should open the box and scan the RMA slip. That should be the only time you touch the return.

Maximize the efficiency of this task by making it easy for employees to receive the products, give the product a grade by marking the disposition, and then restocking the item in Shopify if appropriate.

(A return management platform like ReturnLogic will give your team this functionality and allow them to restock to Shopify with one click. Click here to see the platform in action.)

Once the product is back in inventory, it can then be shipped out again in future orders. Minimizing the turnaround from a return to ready for resale is the key to managing the costs of your returns.

Maximizing the Value of Inventory

“The deeper you dig into reverse logistics, the more of a nightmare it becomes.” – Peter Sobotta

Success in retail rides on inventory. Retailers often face immense pressure to have just enough units to satisfy demand and no excess. But when 30% to 40% of sold merchandise comes back as a return, fulfilling demand precisely can be nearly impossible.

Not to mention that retailers – especially newer ones – have almost no say in the value their excess inventory holds. The bargaining power in a grey market lies with the buyer – typically an off-price department store – who knows the retailer is eager to release the surplus.

This dynamic sets the stage for liquidation marketplaces.

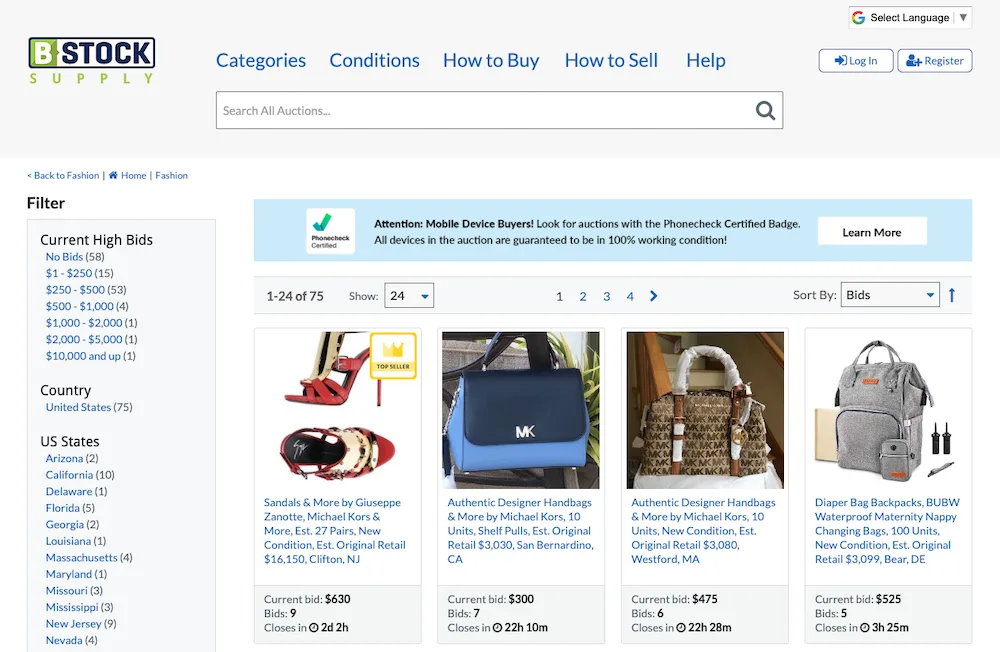

Exploring Liquidation Marketplaces

According to Eric Moriarty, VP of Sales at B-Stock, many of the challenges retailers face in the aftermarket revolve around inventory. Specifically, moving inventory fast and recovering maximum value from returned and excess inventory.

Moriarty describes, “We offer a direct sales channel between sellers and business buyers of aftermarket inventory. This includes returned, excess, and liquidation products.”

B-Stock thrives by taking a one-sided, fragmented market and bringing it closer to a free market driven by supply and demand.

Moriarty explains, “We bring a huge business buyer network and introduce real-time competition for the goods, which produces higher pricing on the merchandise as well as a faster sales cycle.”

Whereas e-commerce retailers were previously left to unload excess and returned merchandise to discount chains or other off-price channels, B-Stock draws a mass of aftermarket buyers interested in bidding on inventory.

This channel moves products fast and achieves a higher recovery value for retailers. Thus, it addresses two of the biggest aftermarket struggles at once.

On top of that, retailers can implement liquidation on a regular schedule with B-Stock. Retailers can list inventory every week or month instead of waiting until the end of the season for a mountain of merchandise to amass.

By efficiently grading returned products as they arrive at the warehouse, retailers minimize the time spent handling goods. Doing so also maximizes the recovery value of returned merchandise since liquidation buyers know exactly what they’re getting when bidding on a pallet.

Sustainably Disposing of Returns

Eventually, around a quarter of returned products will get thrown away by the retailer. This immense physical waste, plus packaging and shipping emissions, make returns one of the greatest threats to environmental sustainability within e-commerce.

Marketplaces like B-Stock provide retailers with a convenient and healthy outlet for their excess inventory, reducing some of the burdens.

However, aftermarket players are increasingly seeking alternative avenues to reduce the imprint of the industry. Whether through re-routing products to charitable organizations or integrating upcycling operations, there are still options with a more positive impact.

At this step in the return management process, retailers need to get creative while ensuring not to over-handle returned items.

In Summary

Return management brings an ever-evolving series of challenges for e-commerce retailers. Remember, within these challenges are hidden opportunities for growth.

Returns optimization focuses on improving the return process, reducing return rate, streamlining operations, and increasing customer lifetime value. Reverse logistics seeks to maximize the recovery value of returned products.

Check out this free Returns Optimization mini-course

D2C brands are the future of e-commerce. But returns are here to stay. Returns Optimization is the path to leverage them for systematic growth.